The Thermographic analysis, carried out with the latest technology from specialized technicians and certified Bureau Veritas - UNI EN ISO 473-971, allow to get a diagnosis on the integrity of the system or the structure examined.

Also in marine, as well as monitoring of machinery, electrical panels main and distribution boards, electric motors and hydraulic systems, thermography allows to inspect and assess the condition of the cargo and possibly discover possible processes of decay of it.

We carry out the same evaluations also in civil and industrial environment to assess the state of the machinery and eventually evaluating maintenance.

In these areas, with the help of a drone with FLIR technology for infrared images and high resolution camera, our qualified technicians are able to perform measurements and visual thermografic of photovoltaic systems, control of coastal areas and the risk areas set pollution, in addition to the overflight of the fields of storage and regasification facilities.

In the building area through thermography we can assess the energy efficiency of the building, leaks or spills, and to supply a map of the same quality. For the purposes of monitoring and conservation of environmental goods and works of historical and archeological, our technicians through the thermographic analysis can assess the integrity of the property.

With the help of a Drone we carry out such analysis even in difficult to reach by man, as well as areas of historical and cultural interest, or sensitive areas such as storage sites.

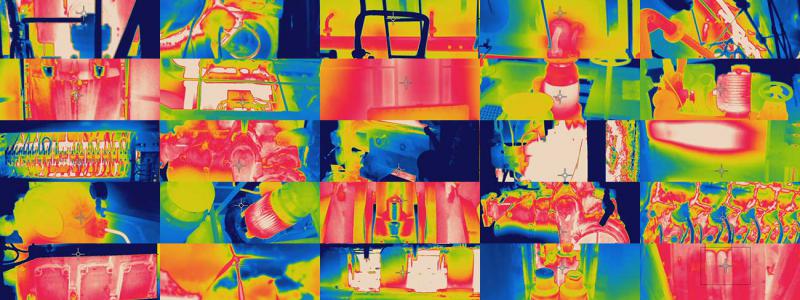

In short, the thermographic analysis can be applied to the following areas:

- Electric

switches, electrical connections, cabinets and panels, electric motors, photovoltaic systems - Mechanic

couplings, adaptor, bearings, sliding elements or rolling, eolic machinery - Hydraulic

valves, piping, thermal insulation, tank silos, boilers, furnaces, incinerators - Building

control surface state structures, rising damp, seepage / leaks, energy efficiency of the building - Archaeological

verification condition buildings, sites, works of art of historical and cultural interest

Advantages of thermographic analysis:

- finds and quantifies inefficiencies before they become failures;

- saves tangible, cost-benefit analysis;

- prevents any risk of burns from accidental contact of hot parts exposed and unprotected;

- increases safety and fire prevention;

- It allows an increase in efficiency and reliability of machinery.

- It allows the reduction of the insurance premium, guaranteed by many insurance in case of regular thermographic inspections of the machinery.